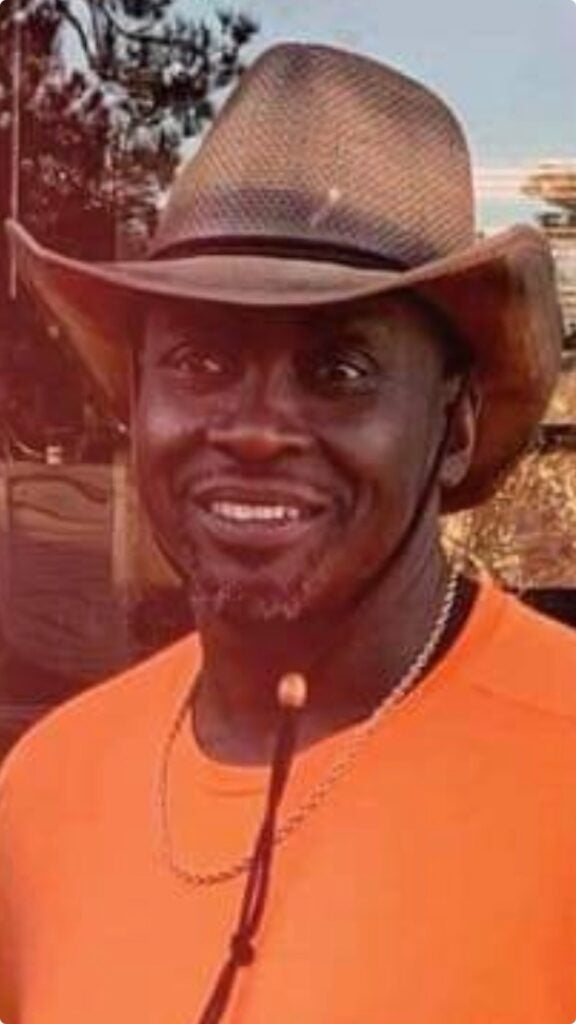

Golden Gourmet OSHA Report on Accident Leading to Tony Lee Stafford’s Death

Published 3:44 pm Wednesday, March 20, 2024

More details have surfaced as to why Golden Gourmet did not report the workplace accident to OSHA that led to Tony Lee Stafford’s death. According to the OSHA report, the QA Manager transported Stafford to the hospital after the accident. She was informed that Stafford would need surgery. The report states that the QA manager was met by a member of the staffing agency at the hospital where “she assumed the staffing agency would report the hospitalization to OSHA.”

The QA manager conveyed this information to the president of the company, along with details pertaining to the surgery Stafford would need. Stafford was hired by The Staffing People, a temp agency who provides workers for various companies. The OSHA report records that the QA manager stated that Golden Gourmet “maintained the OSHA 300 logs for all of the temporary employees and stated they trained and had all supervisory authority over the temporary employees like they were organic employees.”

Stafford was killed after a pallet containing green beans fell off a rack. The OSHA report revealed more details surrounding the incident.

“During the inspection, the CSHO determined through video footage and interview statements, employees were directed and allowed to work in and around a steel storage rack in which a supervisor struck with a powered industrial truck (forklift) and dislodged and bent the front horizontal load bearing cross beam. The shelf in which the damage occurred on contained a pallet containing 56 boxes of individual servings of green beans, which weighed in excess of 1,000 pounds.”

The report details the hazard this created. “After the supervisor and employees determined the damage was so severe the bar could not be put back into place, the supervisor left the load on the shelf, while visibly leaning and unsupported, and pulled a pallet from the top shelf of the steel storage rack.”

The report details how the hazard was left unattended. “The supervisor then pulled the boxes off which were needed, placing them on the floor, directly under the damaged shelf and in the danger zone. Once complete, the supervisor picked the pallet up with his forklift and put it back on the top shelf. Once complete, the supervisor left the area on his forklift, without isolating the area, or alerting the other employees in the area as to the hazard he created. A short while later, an employee, without knowing what happened, drove his forklift and stopped parallel to the damaged rack when he saw the damaged shelf. The employee then dismounted his forklift to look closer, then turned to get back on his forklift when the shelf collapsed onto him, striking him and pinning him against his forklift.”

A statement by the supervisor involved was also included in the report. “The morning of the incident, I went into the dry warehouse to pick the order. I went to get the green beans off the shelf and the fork lift grabbed the bottom of the shelf and picked up one side of the bar. I wasn’t sure what to do because I never had something like this happen.”

He mentioned leaving the area in search of help. “Initially I went up front to get help, but when I started taking role, I forgot about [the] rack until someone came up and said the pallet of green beans fell onto Tony.” The supervisor made further remarks. “I went back to the shelf and put a new bar onto the shelf to replace the bent one. I really don’t know why I didn’t take the pallet off of the shelf before I went up front.”

He mentioned that he had previous forklift experience but was not formally evaluated. “I don’t have a license for the forklift, but I’ve driven one for years. They asked me if I ever drove a forklift before when I started and I said yes. I was not evaluated.” The OSHA report further details the forklift training of the supervisor, stating that both the company president and the employee managing shipping/receiving and forklift training “stated they were aware of the requirements and provided a written forklift safety program which outlined the requirements for training, retraining, and certification, however, they stated they had not yet established a classroom or written portion yet and only conducted training through hands on training and a hands on evaluation.”

OSHA has proposed a $7,813 fine for the employer exposing employees working near and around the steel racking system to struck-by hazards, a $6,250 penalty for the employer not adequately evaluating and certifying employees operating forklifts, and a $7,813 penalty for the employer failing to report a work-related hospitalization to OSHA within 24 hours.

Stafford’s sister, Leslie Johnson, commented: “The Family of the late Tony L. Stafford, Jr. has obtained several attorneys and have filed several lawsuits on behalf of Mr. Stafford’s Estate. No amount of money could ever bring him back but his family can have some sense of closure and obtain answers to a lot of unanswered questions.”

A prior attempt to gain comment from Golden Gourmet was met with a referral to The Staffing People.